Aluminium roestvrij staal kop opening type pompnegel:

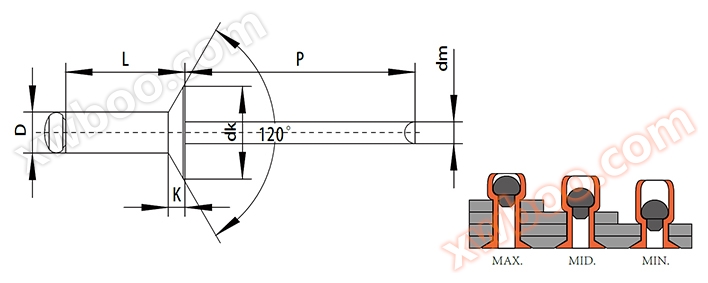

Aluminium roestvrij staal spijker openingstype pompknip is een pompknip die bestaat uit een aluminium spijker met een 120 graden spijker en een roestvrij staal spijker kern.

Kenmerken:

1, breed knijpbereik;

2, hoge sterkte, lage kosten;

Hoge installatie-efficiëntie;

4, voldoen aan de algemene bevestigingseisen, een breed toepassingsgebied;

5, hoge corrosiebestendigheid;

6, het oppervlak na het knippen glad.

Toepassing:

Aluminium roestvrij staal kop pomp kern nieten zijn geschikt voor karton, houten plaat, koppelvlak, glasvezelplaat, asbestplaat, rubberen plaat, ijzeren plaat, ijzeren schil, aluminium profiel, aluminium legeringsplaat, machine naam plaat enz verbinding bevestiging; Veel toegepast in decoratieve gebouwen, decoratie, schepen, auto's, treinen, luchtvaart, elektronische instrumenten, mechanische staalstructuur en andere knijpgebieden; Vooral geschikt voor corrosieve omgevingen.

Parameters:

| D | L | Nieten bereik | Productnaam | dk | k | dm | p | weerstand tegen trekken | Snierweerstand | ||

| 2.4 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| 6.0 | 2.0~3.5 | A2BC-24060 | 4.8 [+0/-0.6] | 0.8 | 1.45 | 27 | 350 | 250 | ||

| [+0.08/-0.10] | 8 | 3.0~5.5 | A2BC-24080 | |||||||

| 10.0 | 5.0~7.5 | A2BC-24100 | ||||||||

| 2.5mm | - | - | ||||||||

| 3.0 | 6.0 | 2.0~3.0 | A2BC-30060 | 6.0 [+0/-0.7] | 1.0 | 1.75 | 27 | 550 | 400 | |

| [+0.08/-0.10] | 8 | 2.5~5.0 | A2BC-30080 | |||||||

| 10.0 | 4.5~7.0 | A2BC-30100 | ||||||||

| 3.1mm | 12 | 6.5~9.0 | A2BC-30120 | |||||||

| 3.2 | 6.0 | 2.0~3.0 | A2BC-32060 | 6.0 [+0/-0.7] | 1.0 | 1.75 | 27 | 700 | 500 | |

| [+0.08/-0.10] | 8 | 2.5~5.0 | A2BC-32080 | |||||||

| 10.0 | 4.5~7.0 | A2BC-32100 | ||||||||

| 3.3mm | 12 | 6.5~9.0 | A2BC-32120 | |||||||

| 14.0 | 8.0~11.0 | A2BC-32140 | ||||||||

| 16 | 9.0~12.5 | A2BC-32160 | ||||||||

| 4.0 | 6.0 | 1.5~2.5 | A2BC-40060 | 7.8 [+0/-0.8] | 1.3 | 2.2 | 27 | 1200 | 850 | |

| [+0.08/-0.15] | 8.0 | 1.5~4.0 | A2BC-40080 | |||||||

| 10.0 | 3.5~6.0 | A2BC-40100 | ||||||||

| 4.1mm | 12.0 | 5.5~8.0 | A2BC-40120 | |||||||

| 14.0 | 7.5~10.0 | A2BC-40140 | ||||||||

| 16.0 | 9.5~12.0 | A2BC-40160 | ||||||||

| 18.0 | 10.0~13.5 | A2BC-40180 | ||||||||

| 20.0 | 11.0~15.5 | A2BC-40200 | ||||||||

| 4.8 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| 8.0 | 2.0~3.5 | A2BC-48080 | 9.0 [+0/-0.5] | 1.5 | 2.7 | 27 | 1700 | 1200 | ||

| 10.0 | 3.0~5.5 | A2BC-48100 | ||||||||

| [+0.08/-0.15] | 12.0 | 5.0~7.5 | A2BC-48120 | |||||||

| 14.0 | 7.0~9.5 | A2BC-48140 | ||||||||

| 4.9mm | 16.0 | 8.0~11.5 | A2BC-48160 | |||||||

| 18.0 | 10.0~13.5 | A2BC-48180 | ||||||||

| 20.0 | 11.0~15.0 | A2BC-48200 | ||||||||

| 25.0 | 15.0~19.0 | A2BC-48250 | ||||||||

| 30.0 | 19.0~24.0 | A2BC-48300 | ||||||||

| 5.0 | 8.0 | 2.0~3.5 | A2BC-50080 | 9.3 [+0/-0.8] | 1.6 | 2.7 | 27 | 2000 | 1400 | |

| 10.0 | 3.0~5.5 | A2BC-50100 | ||||||||

| [+0.08/-0.15] | 12.0 | 5.0~7.5 | A2BC-50120 | |||||||

| 14.0 | 7.0~9.5 | A2BC-50140 | ||||||||

| 5.1mm | 16.0 | 8.0~11.5 | A2BC-50160 | |||||||

| 18.0 | 10.0~13.5 | A2BC-50180 | ||||||||

| 20.0 | 11.0~15.0 | A2BC-50200 | ||||||||

| 25.0 | 15.0~19.0 | A2BC-50250 | ||||||||

| 30.0 | 19.0~24.0 | A2BC-50300 | ||||||||

| 6.0 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| 8.0 | 2.0~2.5 | A2BC-60080 | 11.0 [+0/-0.7] | 1.9 [+0/-0.4] | 3.3 | 31 | 3000 | 2100 | ||

| [+0.08/-0.15] | 10.0 | 2.0~4.5 | A2BC-60100 | |||||||

| 12.0 | 3.0~6.0 | A2BC-60120 | ||||||||

| 6.1mm | 14.0 | 5.0~8.0 | A2BC-60140 | |||||||

| 16.0 | 7.0~10.0 | A2BC-60160 | ||||||||

| 18.0 | 9.0~12.0 | A2BC-60180 | ||||||||

| 22.0 | 13.0~16.0 | A2BC-60220 | ||||||||

| 26.0 | 17.0~20.0 | A2BC-60260 | ||||||||

| 30.0 | 20.0~23.5 | A2BC-60300 | ||||||||

| 33.0 | 23.0~26.5 | A2BC-60330 | ||||||||

| 35.0 | 23.5~28.0 | A2BC-60350 | ||||||||

| 6.4 | 10.0 | 2.5~4.0 | A2BC-64100 | 12.0 [+0/-0.7] | 2.0 [+0/-0.5] | 3.7 | 31 | 3150 | 2200 | |

| 12.0 | 3.5~6.0 | A2BC-64120 | ||||||||

| [+0.08/-0.15] | 15.0 | 6.0~8.5 | A2BC-64150 | |||||||

| 18.0 | 9.0~11.5 | A2BC-64180 | ||||||||

| 6.5mm | 22.0 | 11.5~15.5 | A2BC-64220 | |||||||

| 26.0 | 15.0~19.0 | A2BC-64260 | ||||||||

| 30.0 | 18.0~23.0 | A2BC-64300 | ||||||||

| 33.0 | 20.0~25.5 | A2BC-64330 | ||||||||

| D | L | Nieten bereik | Productnaam | dk | k | dm | p | weerstand tegen trekken | Snierweerstand | ||

| 2.4 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| [+0.08/-0.10] | 6.0 | 2.0~3.5 | A3BC-24060 | 4.8 [+0/-0.6] | 0.8 | 1.45 | 27 | 355 | 315 | |

| 8 | 3.0~5.5 | A3BC-24080 | ||||||||

| 2.5mm | 10.0 | 5.0~7.5 | A3BC-24100 | |||||||

| 3.0 | 6.0 | 2.0~3.0 | A3BC-30060 | 6.0 [+0/-0.7] | 1.0 | 1.75 | 27 | 810 | 550 | |

| [+0.08/-0.10] | 8 | 2.5~5.0 | A3BC-30080 | |||||||

| 10.0 | 4.5~7.0 | A3BC-30100 | ||||||||

| 3.1mm | 12 | 6.5~9.0 | A3BC-30120 | |||||||

| 3.2 | 6.0 | 2.0~3.0 | A3BC-32060 | 6.0 [+0/-0.7] | 1.0 | 1.75 | 27 | 980 | 750 | |

| [+0.08/-0.10] | 8 | 2.5~5.0 | A3BC-32080 | |||||||

| 10.0 | 4.5~7.0 | A3BC-32100 | ||||||||

| 3.3mm | 12 | 6.5~9.0 | A3BC-32120 | |||||||

| 14.0 | 8.0~11.0 | A3BC-32140 | ||||||||

| 16 | 9.0~12.5 | A3BC-32160 | ||||||||

| 4.0 | 6.0 | 1.5~2.5 | A3BC-40060 | 7.8 [+0/-0.8] | 1.3 | 2.2 | 27 | 1600 | 1200 | |

| [+0.08/-0.15] | 8.0 | 1.5~4.0 | A3BC-40080 | |||||||

| 10.0 | 3.5~6.0 | A3BC-40100 | ||||||||

| 4.1mm | 12.0 | 5.5~8.0 | A3BC-40120 | |||||||

| 14.0 | 7.5~10.0 | A3BC-40140 | ||||||||

| 16.0 | 9.5~12.0 | A3BC-40160 | ||||||||

| 18.0 | 10.0~13.5 | A3BC-40180 | ||||||||

| 20.0 | 11.0~15.5 | A3BC-40200 | ||||||||

| 4.8 | 8.0 | 2.0~3.5 | A3BC-48080 | 9.0 [+0/-0.5] | 1.5 | 2.7 | 27 | 2230 | 1690 | |

| [+0.08/-0.15] | 10.0 | 3.0~5.5 | A3BC-48100 | |||||||

| 12.0 | 5.0~7.5 | A3BC-48120 | ||||||||

| 4.9mm | 14.0 | 7.0~9.5 | A3BC-48140 | |||||||

| 16.0 | 8.0~11.5 | A3BC-48160 | ||||||||

| 18.0 | 10.0~13.5 | A3BC-48180 | ||||||||

| 20.0 | 11.0~15.0 | A3BC-48200 | ||||||||

| 25.0 | 15.0~19.0 | A3BC-48250 | ||||||||

| 30.0 | 19.0~24.0 | A3BC-48300 | ||||||||

| 5.0 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| 8.0 | 2.0~3.5 | A3BC-50080 | 9.3 [+0/-0.8] | 1.6 | 2.7 | 27 | 2500 | 2000 | ||

| 10.0 | 3.0~5.5 | A3BC-50100 | ||||||||

| 12.0 | 5.0~7.5 | A3BC-50120 | ||||||||

| 14.0 | 7.0~9.5 | A3BC-50140 | ||||||||

| [+0.08/-0.15] | 16.0 | 8.0~11.5 | A3BC-50160 | |||||||

| 18.0 | 10.0~13.5 | A3BC-50180 | ||||||||

| 5.1mm | 20.0 | 11.0~15.0 | A3BC-50200 | |||||||

| 25.0 | 15.0~19.0 | A3BC-50250 | ||||||||

| 30.0 | 19.0~24.0 | A3BC-50300 | ||||||||

| 6.0 | 8.0 | 2.0~2.5 | A3BC-60080 | 11.0 [+0/-0.7] | 1.9 [+0/-0.4] | 3.3 | 31 | 3900 | 3000 | |

| 10.0 | 2.0~4.5 | A3BC-60100 | ||||||||

| 12.0 | 3.0~6.0 | A3BC-60120 | ||||||||

| 14.0 | 5.0~8.0 | A3BC-60140 | ||||||||

| 16.0 | 7.0~10.0 | A3BC-60160 | ||||||||

| [+0.08/-0.15] | 18.0 | 9.0~12.0 | A3BC-60180 | |||||||

| 22.0 | 13.0~16.0 | A3BC-60220 | ||||||||

| 6.1mm | 26.0 | 17.0~20.0 | A3BC-60260 | |||||||

| 30.0 | 20.0~23.5 | A3BC-60300 | ||||||||

| 33.0 | 23.0~26.5 | A3BC-60330 | ||||||||

| 35.0 | 23.5~28.0 | A3BC-60350 | ||||||||

| 6.4 | 10.0 | 2.5~4.0 | A3BC-64100 | 12.0 [+0/-0.7] | 2.0 [+0/-0.5] | 3.7 | 31 | 4100 | 3120 | |

| 12.0 | 3.5~6.0 | A3BC-64120 | ||||||||

| 15.0 | 6.0~8.5 | A3BC-64150 | ||||||||

| [+0.08/-0.15] | 18.0 | 9.0~11.5 | A3BC-64180 | |||||||

| 22.0 | 11.5~15.5 | A3BC-64220 | ||||||||

| 6.5mm | 26.0 | 15.0~19.0 | A3BC-64260 | |||||||

| 30.0 | 18.0~23.0 | A3BC-64300 | ||||||||

| 33.0 | 20.0~25.5 | A3BC-64330 | ||||||||

| D | L | Nieten bereik | Productnaam | dk | k | dm | p | weerstand tegen trekken | Snierweerstand | ||

| 3.2 | +0.9/-0 | min. ~ max. | ref. | min. | [ N ] | [ N ] | ||||

| [+0.08/-0.10] | 6.0 | 2.0~3.0 | A5BC-32060 | 6.0 [+0/-0.4] | 1.0 | 1.75 | 27 | 1100 | 750 | |

| 8.0 | 2.5~5.0 | A5BC-32080 | ||||||||

| 3.3mm | 10.0 | 4.5~7.0 | A5BC-32100 | |||||||

| 12.0 | 6.5~9.0 | A5BC-32120 | ||||||||

| 4.0 | 6.0 | 1.5~2.5 | A5BC-40060 | 7.5 [+0/-0.4] | 1.3 | 2.1 | 27 | 1800 | 1250 | |

| [+0.08/-0.15] | 8.0 | 1.5~4.0 | A5BC-40080 | |||||||

| 10.0 | 3.5~6.0 | A5BC-40100 | ||||||||

| 4.1mm | 12.0 | 5.5~8.0 | A5BC-40120 | |||||||

| 4.8 | 8.0 | 2.0~3.5 | A5BC-48080 | 9.0 [+0/-0.5] | 1.5 | 2.7 | 27 | 2600 | 1850 | |

| [+0.08/-0.15] | 10.0 | 3.0~5.5 | A5BC-48100 | |||||||

| 12.0 | 5.0~7.5 | A5BC-48120 | ||||||||

| 4.9mm | 14.0 | 7.0~9.5 | A5BC-48140 | |||||||

| 16.0 | 8.0~11.5 | A5BC-48160 | ||||||||

| 18.0 | 10.0~13.5 | A5BC-48180 | ||||||||

| 20.0 | 11.0~15.0 | A5BC-48200 | ||||||||

Standaarden:

Xingyu Company levert aluminium roestvrij staal kop opening type pompnegel, is afgeleid van de nationale standaard, de productie is gebaseerd op aluminium staal kop opening type pompnegel standaard uitgevoerd, afhankelijk van het magnesiumgehalte hoog en laag overeenkomt met verschillende soorten;

1, verwijzing naar de nationale standaard en de overeenkomstige internationale norm (ISO) van aluminium staal sinkop opening type pomp kern nieten als volgt:

GB/T 12617.1-2006 openingstype onderkop openingstype pompnegel 10, 11 graden (equivalent aan ISO 15977: 2002);

2, de Amerikaanse standaard IFI-114-2003 Break Mandrel Blind Rivets voor aluminium staal zinkende kop openingstype pompkern;

De Duitse standaard is DIN7337-1991 Break Mandrel Blind Rivets, B-kopvorm;

4, aluminium roestvrij staal kop opening type pomp kern nieten kan worden geselecteerd door de diameter serie van 2.4, 3.2, 4.0, 4.8, 5.0, 6.0, 6.4, 8.0, zie de specificaties parameters tabel;

De inspectiemethode van het product is volgens GB / T 3098.18-2004 (ISO14589: 2000), de prestatie-indicator is GB / T 3098.19-2004.

|

Materiaal |

Serienaam |

|

5052 (aluminiumlegering met 2,5% magnesium) rivet en spijker uit roestvrij staal |

A2BC |

|

5154 (aluminiumlegering met 3,5% magnesium) rivet en spijker uit roestvrij staal |

A3BC |

|

5056 (aluminiumlegering met 5,0% magnesium) rivet en roestvrijstalen spijkkern |

A5BC |